admin:Date:2026-01-22Hits:2

With the rapid expansion of the global additive manufacturing industry, PETG (Polyethylene Terephthalate Glycol) has become one of the most widely adopted and fastest-growing materials in 3D printing. Known for its excellent transparency, toughness, chemical resistance, and processing stability, PETG is increasingly positioned as a versatile solution bridging consumer-grade and industrial-grade applications.

Recent market data indicates that the global PETG market exceeded USD 2.2 billion in 2025 and is projected to approach USD 3.8 billion by 2035, maintaining a compound annual growth rate (CAGR) of over 6%. This growth is driven by rising demand from packaging, medical devices, industrial manufacturing, and especially 3D printing filament applications.

At the center of this growth lies a critical but often underestimated factor: slicing technology.

PETG Slicing: Turning Material Potential into Performance

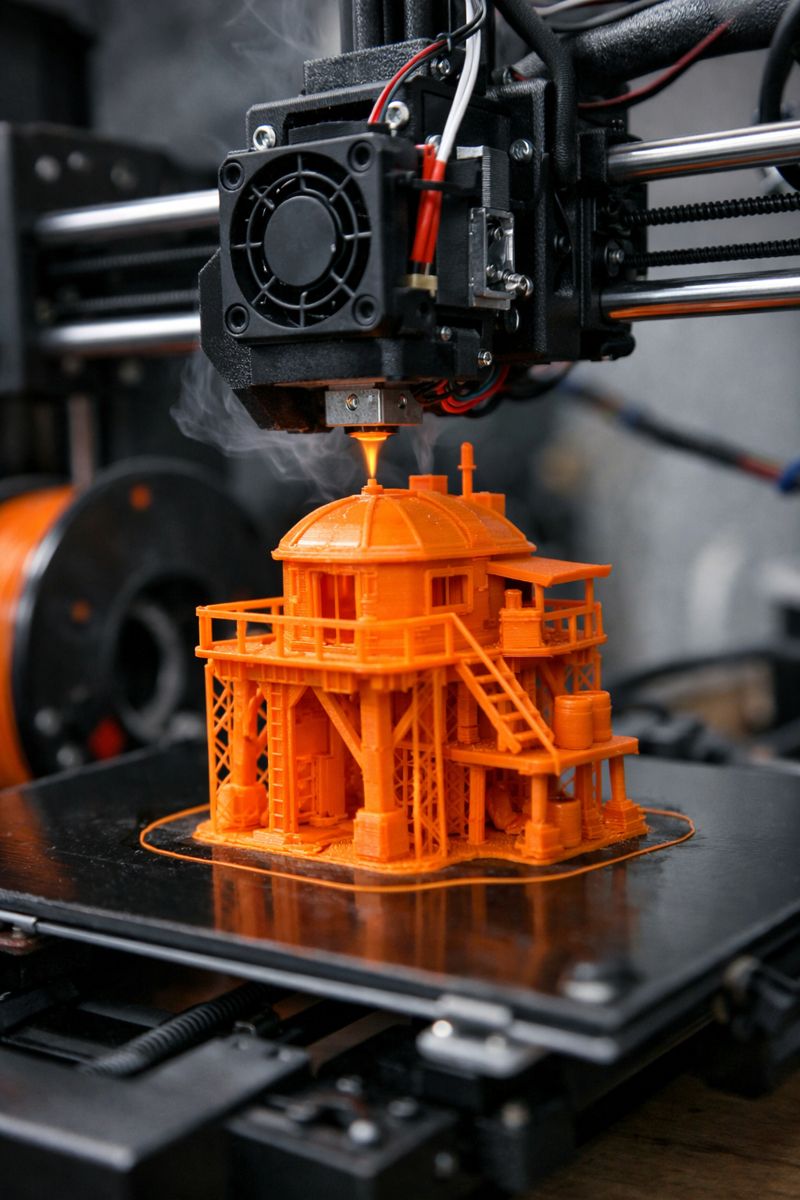

In 3D printing, slicing is the key process that converts a digital model into precise machine instructions. For PETG materials, slicing parameters directly determine final part quality, production efficiency, and material utilization.

Modern slicing software allows manufacturers to fine-tune critical parameters such as:

•Layer height and extrusion width

•Printing temperature and cooling strategy

•Infill pattern, density, and wall thickness

•Printing speed and toolpath direction

Optimized PETG slicing profiles significantly improve layer adhesion, surface smoothness, dimensional accuracy, and mechanical strength, while minimizing common challenges such as stringing or deformation. As slicing algorithms evolve toward automation and intelligence, PETG printing becomes more consistent, scalable, and cost-effective.

From Prototyping to Production: PETG Enters Industrial Manufacturing

Once regarded mainly as a consumer-level filament, PETG is now gaining strong momentum in industrial and professional 3D printing environments. Research and industrial practice have shown that adjusting slicing orientation and structural infill strategies can dramatically enhance PETG’s tensile strength and impact resistance.

As a result, PETG is increasingly used in:

•Functional prototypes and low-volume production

•Jigs, fixtures, and tooling components

•Lightweight industrial housings and brackets

•Customized mechanical and electronic parts

The continuous growth of the global 3D printing filament market further reinforces the importance of optimized PETG slicing workflows, especially for enterprises pursuing higher productivity and repeatable quality.

Expanding Applications Across Multiple Industries

Thanks to its balanced material properties, PETG supports a wide range of applications across different industries:

•Consumer Products & Home Applications

PETG is commonly used for transparent containers, organizers, and decorative items due to its durability, moisture resistance, and aesthetic clarity.

•Medical & Healthcare Equipment

PETG’s chemical stability and transparency make it suitable for customized medical devices, protective equipment, and components requiring visual inspection.

•Industrial & Engineering Applications

In automotive, robotics, and electronics manufacturing, PETG serves as a lightweight and cost-effective alternative for functional parts, enclosures, and support components.

In addition, PETG’s recyclability aligns with growing global sustainability requirements. Ongoing development of recycled PETG filaments further strengthens its role in environmentally responsible and circular manufacturing systems.

Future Outlook: Intelligent Slicing and Smart Manufacturing

Looking ahead, the integration of AI-assisted slicing, simulation-based optimization, and digital manufacturing platforms will further elevate PETG’s role in advanced manufacturing. Intelligent slicing systems are expected to automatically adapt printing strategies based on material behavior, geometry complexity, and performance requirements.

As industries continue to move toward digitalization, customization, and sustainable production, PETG slicing technology will remain a critical link between material science and intelligent manufacturing—enabling faster innovation cycles, higher-quality output, and stronger competitive advantages for enterprises worldwide.

Copyright 2019 Jiangyin Film-Maker Plastic Co., Ltd.